The embossing process of embossed PVC marble sheets and related panels primarily relies on extrusion technology, ensuring efficient and consistent production.(Figure 1)(Figure 2)

First, the extrusion process forms the base PVC sheet. Then, through the hot press lamination process (hot pressing and laminating), the various colored film papers are tightly attached to the surface of the sheet, giving it rich color expression, which lays the foundation for achieving a variety of visual effects such as imitation stone or marble treatment.(Figure 3)(Figure 4)

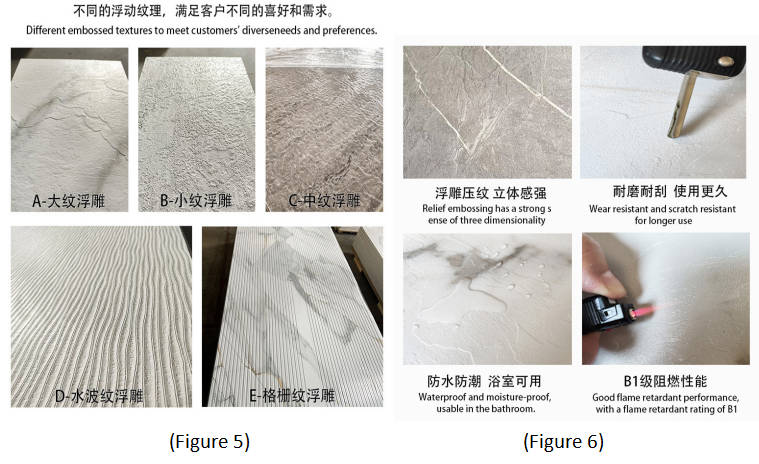

The key step to create the embossed texture is the pressing with embossing rollers. These rollers come in a variety of patterns, including large patterns, small patterns, water ripples, and grille patterns. When the PVC sheet, after lamination, passes through the embossing rollers under controlled temperature and pressure, the specific textures on the rollers are precisely transferred onto the surface. This process results in distinct relief effects, making the panels have a three-dimensional and tactile finish.(Figure 5)(Figure 6)

This combination of extrusion, heat pressing lamination, and embossing roller pressing allows the production of PVC panels with various colors and embossed patterns, such as grille pattern PVC stone vein panels. It effectively meets the diverse preferences and practical needs of different customers in interior decoration and other fields.

Post time: Jul-31-2025